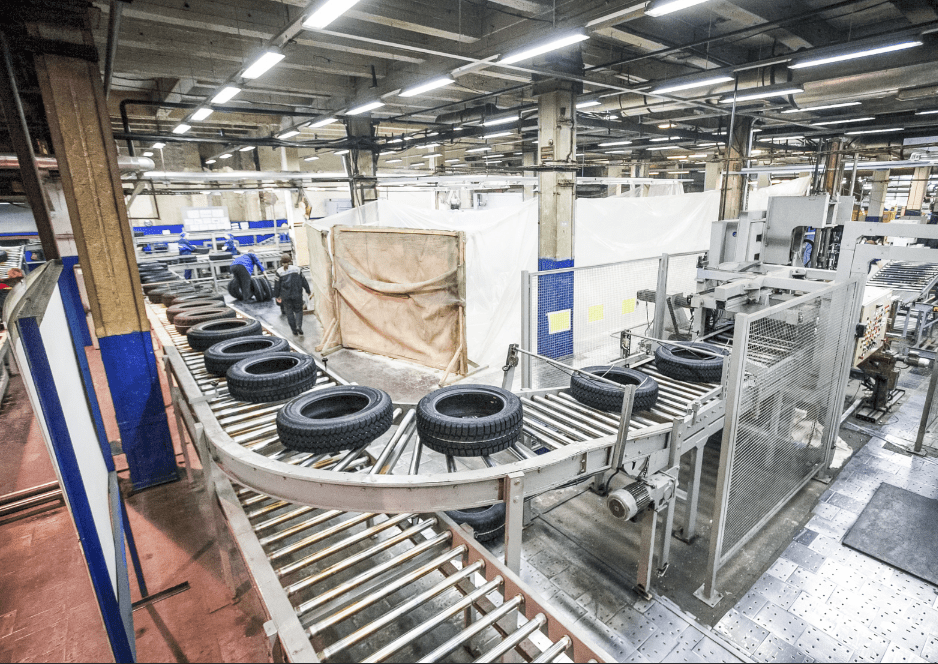

Have you ever wondered how tyres are made? The tyre manufacturing industry is an energy-intensive sector that requires large amounts of thermal energy to produce high-quality tyres. It’s a complex production process that includes mixing, calendaring, extruding, curing and vulcanization. But the production process also generates a significant amount of waste heat that needs to be removed to maintain the required temperature. This is why energy costs can be astronomical for tyre manufacturers, making it hard to maintain profitability. But thanks to energy-efficient sustainable InDirect Evaporative Cooling (IDEC) systems, tyre manufacturers can reduce energy consumption and improve operational efficiency – giving them the best return on investment.

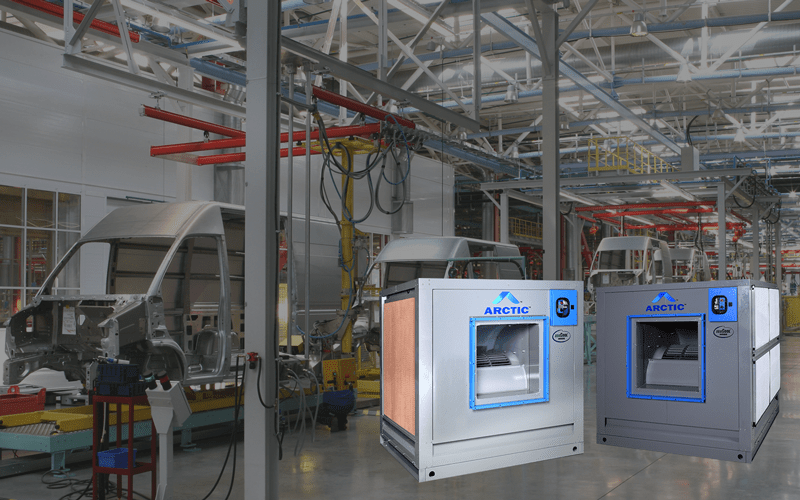

ARCTIC’s IDEC delivers a breakthrough in cooling technology – combining indirect evaporative cooling modules and a direct cooling segment to achieve a cooler dry bulb temperature than that of a direct evaporative cooler alone. Experience top-of-the-line cooling performance with this two-stage evaporative cooling system.

Advantages of ARCTIC InDirect Evaporative Cooling (IDEC) Systems for Tyre Industry

InDirect Evaporative Cooling (IDEC) systems are a type of cooling system that can provide significant benefits for tyre manufacturing plants. These systems work by using the natural cooling properties of water to cool the air in a closed loop system, which can help to reduce the energy consumption and costs associated with cooling tyre manufacturing plants.

Here are some of the advantages of IDEC systems for the tyre industry:

- Energy Efficiency: IDEC systems are incredibly energy-efficient, and they can help to reduce the energy consumption of tyre manufacturing plants. Unlike traditional cooling systems that use electricity to cool the air, IDEC systems use the natural cooling properties of water to cool the air. This makes them much more energy-efficient, which can lead to significant cost savings for tyre manufacturers.

- Reduced Carbon Footprint: IDEC systems are also much more environmentally friendly than traditional cooling systems. They don’t require any electricity to cool the air, which means they don’t produce any carbon emissions. This makes them a more sustainable and environmentally friendly option for tyre manufacturing plants that want to reduce their carbon footprint and be more eco-friendly.

- Improved Air Quality: IDEC systems can also help to improve the air quality in tyre manufacturing plants. These systems use water to cool the air, which means that they can help to remove pollutants and other airborne contaminants from the air. This can create a cleaner, healthier work environment for employees in the plant.

- Reduced Maintenance Costs: IDEC systems require less maintenance than traditional cooling systems. These systems don’t have any moving parts, which means they don’t require as much maintenance as traditional cooling systems that rely on fans and other mechanical components. This can help to reduce maintenance costs and increase the reliability of the cooling system.

- Longevity: IDEC systems are also built to last. These systems are made from high-quality materials and are designed to be durable and long-lasting. This means that tyre manufacturers can rely on them to provide efficient cooling for many years, which can help to reduce the need for costly replacements or repairs.

- Improved Productivity: IDEC systems can also help to improve the productivity of tyre manufacturing plants. These systems can provide a comfortable working environment for employees, which can help to reduce fatigue and improve focus. This can lead to increased productivity and efficiency in the plant, which can help to improve the bottom line for tyre manufacturers.

In nutshell, InDirect Evaporative Cooling (IDEC) systems are a highly effective and energy-efficient cooling solution for tyre manufacturing plants. These systems can provide a range of benefits, including reduced energy consumption, improved air quality, reduced maintenance costs, and increased productivity. With these benefits in mind, it’s easy to see why IDEC systems are becoming an increasingly popular choice for tyre manufacturers who are looking to reduce their costs and become more environmentally friendly.

The Arctic InDirect Evaporative Coolers (IDEC) bring incredible benefits to the table. Check out some of their distinctive features:

- Double skin casing – outer casing made of pre-coated sheets

- High efficiency centrifugal fans

- High Efficiency (90%+) long life evaporative EcoCool pads

- No harmful refrigerants or ozone depleting chemicals

- AHRI Certified casing for Leakage

- Fully factory manufactured and tested units

- Ready to use, plug & play

- Pre-Coated Galvanised Steel

- Centrifugal

What to Consider When Choosing a Sustainable IDEC System?

When selecting a sustainable InDirect Evaporative Cooling (IDEC) system for tyre manufacturing plants, there are few critical factors that should be considered. These include:

- System Efficiency: The efficiency of the cooling system is a crucial factor to consider when selecting a sustainable indirect cooling system. A more efficient system will result in lower energy consumption and higher cost savings for the tyre manufacturer.

- Cost: The cost of the cooling system is another important factor to consider. The system should be affordable and provide a good return on investment for the tyre manufacturer.

- Reliability: The reliability of the cooling system is also an essential factor to consider. The system should be designed to operate reliably over an extended period without requiring frequent maintenance.

- Ease of Installation and Maintenance: The ease of installation of the cooling system is also an important consideration. The system should be easy to install and maintain in a longer run.

Discover why ARCTIC Cooling Solutions should be the first choice for your tyre manufacturing plant.

At ARCTIC, the knowledge experts have years of experience in evaluating the cooling needs of different industries, including tyre manufacturing plants. They have in-depth knowledge of the latest technological advancements and sustainability practices in cooling systems, which allows them to provide valuable insights and suggestions for the best suitable solutions.

ARCTIC’s team of experts work closely with tyre manufacturing plant managers to understand their cooling requirements, challenges, and goals. Based on this analysis, they suggest custom-designed and cost-effective solutions that can improve energy efficiency, reduce carbon footprint, and optimize overall plant performance. Additionally, ARCTIC’s experts provide comprehensive support throughout the installation, operation, and maintenance process, ensuring the best possible outcomes for tyre manufacturers.