The Necessity of Air Conditioning in Large Spaces

In the modern era, the significance of air conditioning units, especially commercial coolers, in expansive areas is immensely crucial. These systems are essential in creating a comfortable and safe environment in various commercial spaces. However, they must include the possibility of lower air quality due to poor maintenance and the possibility of mechanical failures, which can present significant health and safety issues.

Understanding Commercial Coolers

A commercial cooler is more than just a large-scale air conditioning unit. It is an essential component in industries where temperature control is critical. From manufacturing plants to large office spaces, the role of a commercial air cooler is pivotal in ensuring a consistent and safe environment.

Health and Safety Regulations: A Closer Look

Regulatory Compliance

Complying with health and safety standards is more than a legal necessity; it’s an ethical responsibility for companies. Such regulations are established to guarantee the secure functioning of commercial coolers. They cover aspects such as installation, maintenance, and emergency procedures. Regular inspections and adherence to these regulations are crucial in preventing accidents and ensuring the longevity of the equipment.

Best Practices in Maintenance

Regular maintenance of commercial coolers is essential. This includes routine checks and cleaning of filters, coils, and ducts to ensure efficient operation and prevent the circulation of harmful contaminants. Businesses should establish a maintenance schedule in line with the manufacturer’s recommendations and local safety regulations.

Training and Awareness

Employees working around commercial coolers should be adequately trained. This training should cover operational procedures, emergency protocols, and basic troubleshooting. Awareness of potential hazards and how to avoid them is crucial in maintaining a safe working environment.

The Indian Context

In India’s market, air conditioners are dominating in market share, propelled by expansion in the household sector and the development of new residential buildings. Additionally, the increase in construction activities is amplifying the need for air conditioning systems, which are turning into a necessity in residential properties.

BIS certification is mandatory for air conditioners and related components like room air conditioners, heat exchangers, hermetic compressors, and temperature-sensing control devices. Products with BIS certification and the ISI mark are assured to be of high quality and in compliance with the relevant Indian standards.

Now, let’s delve into what BIS and the BIS license entail.

The Bureau of Indian Standards (BIS) is an organization in India responsible for establishing, grading, and developing standards for consumer products. The Bureau of Indian Standards (BIS) in India sets, classifies, and evolves standards for consumer goods. BIS manages the certification of product quality, aiming to guarantee their quality, longevity, and dependability for users.

The BIS license is part of the ISI Mark certification scheme managed by the Bureau. This license allows manufacturers to use the ISI mark on products that meet the required Indian standards.

The Ministry of Commerce and Industry issued the “Air Conditioner and its related Parts, Hermetic Compressor, and Temperature Sensing Controls (Quality Control) Order, 2019”. This order mandates compliance with Indian standards and the use of the ISI mark.

Under this Quality Control Order (QCO), air conditioners, related parts, hermetic compressors, and temperature sensing controls must conform to the respective Indian standards and bear the ISI mark under a BIS license, as per Scheme I of Schedule-II of the Bureau of Indian Standard (Conformity Assessment) Regulations, 2018.

This standard outlines the design and performance requirements for air conditioners, related components, hermetic compressors, and temperature sensing controls, including test conditions and procedures for assessing various performance aspects.

Manufacturers seeking to market air conditioners in India must obtain BIS certification to use the standard mark. The BIS Certificate for air conditioners, hermetic compressors, and related parts is granted only after confirming compliance with all relevant Indian standards. To acquire a BIS License for air conditioners, temperature sensing control devices, and related parts, manufacturers must ensure their products meet all applicable Indian standards.

Securing a BIS license enables businesses to build consumer trust, guarantee consumer safety, and ensure their products are safe and free from physical hazards.

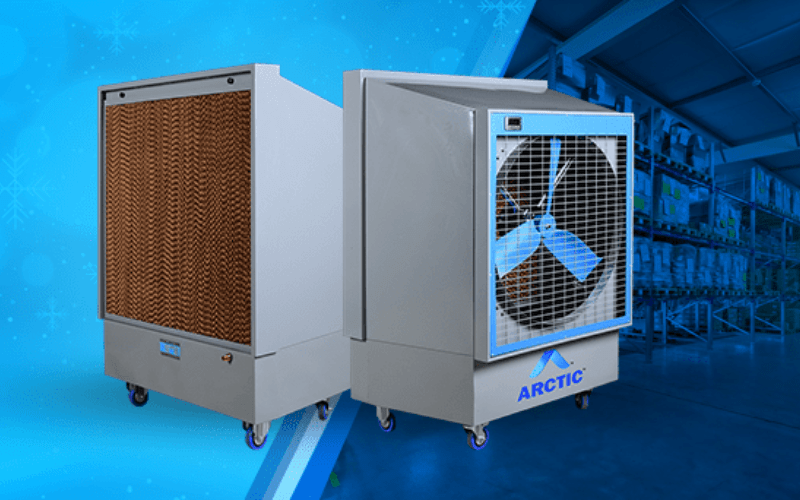

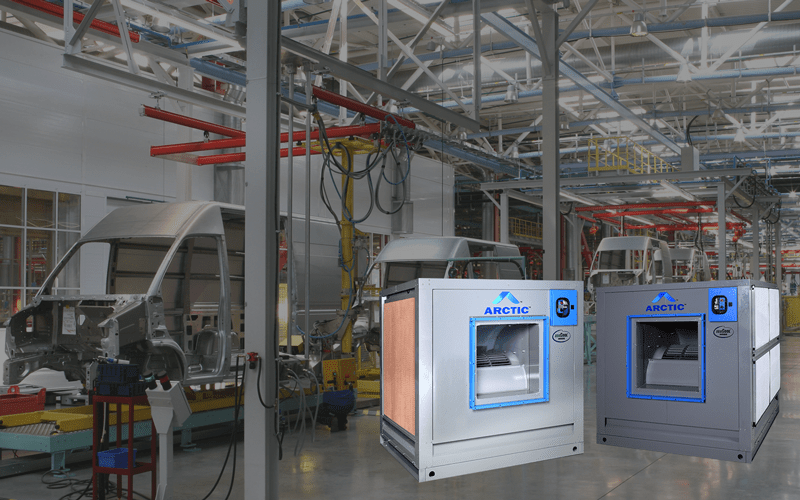

Why Choose Yes Arctic?

In order to provide ideal cooling solutions for big spaces and provide a safe and comfortable environment, Yes Arctic offers a selection of commercial and industrial air coolers that are not only efficient but also meet the highest safety standards.

Commitment to Safety and Quality

At Yes Arctic, the commitment to safety and quality is paramount. Their products undergo rigorous testing to ensure they meet industry standards. Also, Yes Arctic provides comprehensive support and maintenance services, ensuring that our commercial coolers operate safely and efficiently.

Businesses must grasp and adhere to health and safety standards for commercial coolers. Consistent upkeep, adequate training, and selecting appropriate equipment are fundamental for a secure and effective operation. With firms such as Yes Arctic, businesses can be confident that their air-cooling requirements are being managed safely, offering products that are not only effective but also fully meet all safety guidelines.